H2/H3 - Inaccurate EM Moisture or NIR Constituent Data

8 Nov 2024

Potential Causes

- Lab moisture meter not reading correctly or EM sensor has not been calibrated to lab moisture meter

- Not enough grain to fill the test cup assembly

- Trashy sample

- Moisture blade or NIR dome has trash or debris on it

- Defective EM moisture or NIR sensor

Potential Fixes

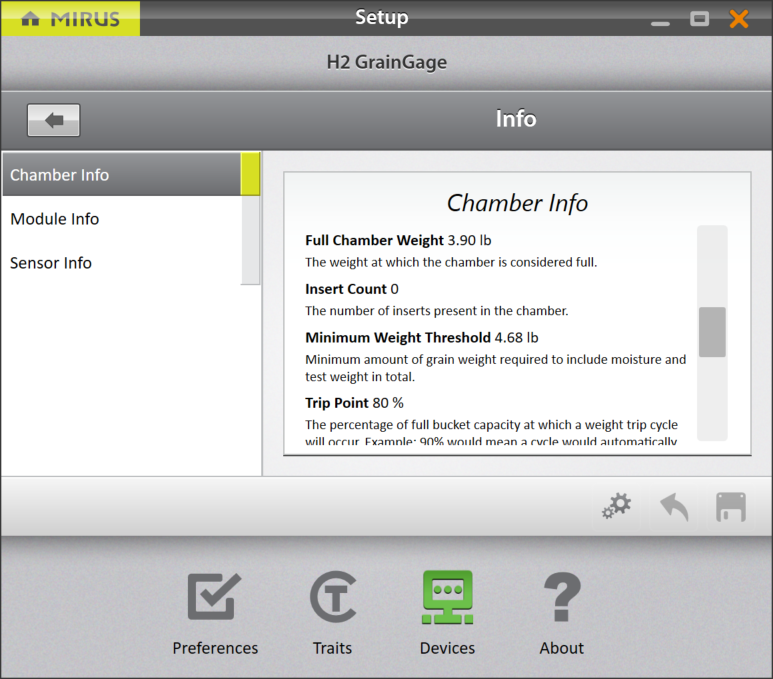

- Check to ensure you are meeting the minimum weight threshold. The minimum weight threshold is the minimum amount of grain required for accurate moisture and test weight data. By default, if the minimum weight threshold is not met, moisture and test weight data will be recorded as zero and/or not included in the plot average when taking sub-samples. To ensure the plots are yielding enough grain to measure accurate data,

Go to Setup > Info > Chamber Info.

- If you are not harvesting enough grain to meet the minimum weight threshold, install low yield inserts and recalibrate the chamber. For more information about low yield inserts, see the H2 GrainGage Hardware Manuals.

- If installing low yield inserts doesn’t work, you may lower the minimum weight threshold to 15%. If reducing any lower than 15%, the test weight measurements should be verified because the test cup might not be filling consistently between plot varieties.

- Inspect and clean the moisture blade or SCiO sensor glass dome (use soft cotton cloth, soap, and water) .

- Touch the blade while watching the change in moisture readings within Diagnostics.

- Check sensor temperature to ensure it is within 5–10 degrees of the current ambient air temperature. For SCIO sensor, see "H3 SCiO Sensor Maximum Operating Temperature."

- Check the supply voltage to ensure it is between 12 and 14 volts.

- Check to ensure the EM moisture blade (inside chamber) and sensor mounting screws are secure. See "EM2 & EM3 Moisture Retare Warnings and/or Fluctuating Moisture Readings" for further details.

For further assistance, contact the HarvestMaster Field Service Engineers.

- Phone Number: 435-753-1881

- Email: hmtechsupport@junipersys.com